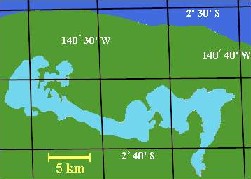

Kulit Kayu is a piece of cloth made from a sheet of bark which is processed into canvas and then painted. In the local language, the fibrous bark cloths are known as ‘maro’ or ‘tapa’. Tapa cloths are made on Asei, one of the islands of Lake Sentani, which is situated approximately 30 km west of the capital Jayapura.

Kulit Kayu is a piece of cloth made from a sheet of bark which is processed into canvas and then painted. In the local language, the fibrous bark cloths are known as ‘maro’ or ‘tapa’. Tapa cloths are made on Asei, one of the islands of Lake Sentani, which is situated approximately 30 km west of the capital Jayapura.

Tapa was formerly used for women’s clothing but these days it is made to sell to tourists as a source of income. This development is not only due to influence from abroad, but is also related to the Sentani people’s interest in their own identity and cultural traditions. As soon as tourists arrive, the Tapa cloths are put out on display along the beach.

Content

1. The bark of Mulberry and Fig trees

1. The bark of Mulberry and Fig trees

2. Harvesting the bark

3. Processing the bark

4. Washing, mounting and drying the bark

5. Painting the Tapa cloths

6. Designs and motifs

7. Links

8. Sources

1 . The bark of Mulbury and Fig trees

Suitable bark for Tapa cloth is mainly collected from mulberry and fig trees. The structure can vary from coarse to fine and smooth to stiff. The colour varies from light to dark grey and includes various shades of brown. Thicker varieties of bark need to soak in water for a few days, while other varieties can be processed immediately to make a thin and flexible cloth.

Suitable bark for Tapa cloth is mainly collected from mulberry and fig trees. The structure can vary from coarse to fine and smooth to stiff. The colour varies from light to dark grey and includes various shades of brown. Thicker varieties of bark need to soak in water for a few days, while other varieties can be processed immediately to make a thin and flexible cloth.

One of the few people who excels at the art of bark cloth making, is August Ongge. Together with three other men, he goes out in a rental car every 3 months to collect a large amount of bark. He needs to drive for a few hours to get this bark. There used to be a lot of forest a round Lake Sentani but because of the increasing population, a lot of trees have been cut. Forestry companies have logged in the area to obtain hard wood.

round Lake Sentani but because of the increasing population, a lot of trees have been cut. Forestry companies have logged in the area to obtain hard wood.

Ongge and his men mainly use the bark of the Kombo, a Mulberry tree. They do not need to replant these trees as they do self-seed quite well. Mulberry regrows, up to five times, after it has been cut down.

2.Harvesting the Bark

The felling of the tree is done with a machete, preferably at full moon. At this time, the juices are well distributed over the tree and bark comes off more easily. After felling the tree, it is divided into separate pieces. The most suitable parts for making Tapa cloth, are the pieces between the knots. Notches are cut into the bark, right up to where it meets the wood: twice around the circumference and once lengthwise. The bark is then loosened very gently along the length of the trunk. This is done first with a machete, then with a kind of wedge, which is made there and then from one of the branches. The wedge is jiggled very carefully from side to side in order to separate the bark from the tree. The last piece of bark is pulled off by hand.

The felling of the tree is done with a machete, preferably at full moon. At this time, the juices are well distributed over the tree and bark comes off more easily. After felling the tree, it is divided into separate pieces. The most suitable parts for making Tapa cloth, are the pieces between the knots. Notches are cut into the bark, right up to where it meets the wood: twice around the circumference and once lengthwise. The bark is then loosened very gently along the length of the trunk. This is done first with a machete, then with a kind of wedge, which is made there and then from one of the branches. The wedge is jiggled very carefully from side to side in order to separate the bark from the tree. The last piece of bark is pulled off by hand.

3. Processing the bark

After the bark has been removed, it has to be worked immediately. If you wait for too long, it will dry out and start to curve. Three types of tools are used for processing: A flat iron bar, a heavy wooden club and a hammer. Working the bark is done in two phases.

After the bark has been removed, it has to be worked immediately. If you wait for too long, it will dry out and start to curve. Three types of tools are used for processing: A flat iron bar, a heavy wooden club and a hammer. Working the bark is done in two phases.

The first phase consists of pressing the bark with the iron bar held diagonally, from left to right across the bark. If you were to move straight up and down along the length of the bark, the fiber would be damaged. The tapping happens on the rough side of the bark which eventually becomes the back of the Tapa cloth. The diamond pattern that is created by working the iron bar in two directions across the bark, is removed by working it with the wooden club.

During the second phase, the bark is folded lengthwise and once again worked with the flat iron bar. The hammer is used a number of times after the folding of the bark in order to flatten it further. The end result is a thin canvas more than four times the size of the original piece of bark. It now feels like chamois.

4. Washing, stretching and drying the bark

The processed bark cloth canvas is rinsed in water to ensure that the juices and resin are removed. If is not rinsed out, the canvas will turn black during the drying process. After washing it for just a few minutes, the canvas is mounted on a stretching frame constructed from the stems of the Sago Palm leaf. The soft cloth is carefully attached with some nails and dried in the sun. Within half an hour, the canvas or Tapa cloth is dry.

The processed bark cloth canvas is rinsed in water to ensure that the juices and resin are removed. If is not rinsed out, the canvas will turn black during the drying process. After washing it for just a few minutes, the canvas is mounted on a stretching frame constructed from the stems of the Sago Palm leaf. The soft cloth is carefully attached with some nails and dried in the sun. Within half an hour, the canvas or Tapa cloth is dry.

5. Painting the Tapa cloth

The artists use various techniques to paint the canvas:

The artists use various techniques to paint the canvas:

• by hand

• with the use of templates which they have designed themselves

• a combination of both

The artist uses black paint to draw the design onto the canvas. To actually paint and eventually colour it in, he uses small sticks that have been flattened on one side to produce a brush. The colouring in requires a lot of patience. For big Tapa cloths, it can take absolutely hours. Quite often a number of people will work on a piece of art, including children.

The most commonly used colours are black, white and ochre. Green and yellow are also used, but not as often. Since the introduction of chemically-based paint, there are also some paintings which have grey, yellow, green and pink. Originally, only natural pigments were used. The red-brown or ochre is made by adding water to a red clay. The yellow was probably made in the same way, using a yellow clay. White paint is made from burnt shells, which are pounded into a fine powder. Black paint is made from a mixture of soot and charcoal; green from plant juice. Except for the green, all the paints keep their colour. Soot is in fact very stable and adheres itself well to material. Apart from the black – as long as it is based on soot- all the colours tend to wash out in water or whenever it rains.

The most commonly used colours are black, white and ochre. Green and yellow are also used, but not as often. Since the introduction of chemically-based paint, there are also some paintings which have grey, yellow, green and pink. Originally, only natural pigments were used. The red-brown or ochre is made by adding water to a red clay. The yellow was probably made in the same way, using a yellow clay. White paint is made from burnt shells, which are pounded into a fine powder. Black paint is made from a mixture of soot and charcoal; green from plant juice. Except for the green, all the paints keep their colour. Soot is in fact very stable and adheres itself well to material. Apart from the black – as long as it is based on soot- all the colours tend to wash out in water or whenever it rains.

6. Designs and Motifs

Traditional drawings and images are commonly used for the designs on Tapa. Parts of the drawings have been handed down form one generation to the next. However, a lot of the knowledge has been lost. For this reason the people of Asei make use of artefacts and drawings collected and recorded by anthropologists and interested laymen. A frequently used publication is the book Maro Paintings of Lake Sentani and Humboldt Bay, edited by J. Hoogerbrugge.

Traditional drawings and images are commonly used for the designs on Tapa. Parts of the drawings have been handed down form one generation to the next. However, a lot of the knowledge has been lost. For this reason the people of Asei make use of artefacts and drawings collected and recorded by anthropologists and interested laymen. A frequently used publication is the book Maro Paintings of Lake Sentani and Humboldt Bay, edited by J. Hoogerbrugge.  Now and then people use a design of their own. Almost always the design is based on a particular story and/or it is related to spiritual issues, their ancestors, important spirits and symbols (of animals and supernatural signs). The drawings also tell the story of everyday life in the village or in the bush. The most common motifs are the spiral and abstract designs of fish and animals. These days there is an increasing demand for the use of imagery based on Christianity.

Now and then people use a design of their own. Almost always the design is based on a particular story and/or it is related to spiritual issues, their ancestors, important spirits and symbols (of animals and supernatural signs). The drawings also tell the story of everyday life in the village or in the bush. The most common motifs are the spiral and abstract designs of fish and animals. These days there is an increasing demand for the use of imagery based on Christianity.

7. Links

http://www.teara.govt.nz/1966/M/MaoriMaterialCulture/ClothingAndAdornment/en

8. Sources

- Hermkens, A.K. 1998. Report of a lecture

- Hermkens, A.K. Essay and Thesis

- Kamma, C. 'Van boom tot maro' (inluding photos) A personal document.